Call us on

+31(0)10 31 32 100

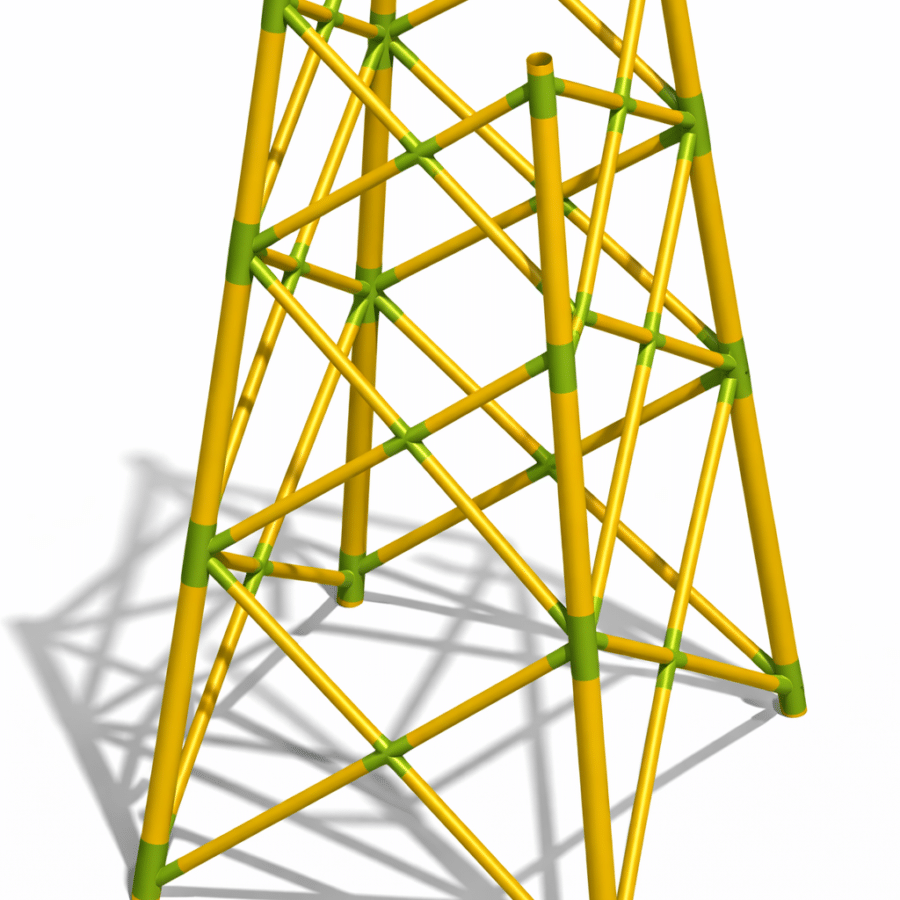

R&D Jacket foundations for 14MW & 20MW WTG (WNI & WNII)

Project Name: R&D Jacket foundations for 14MW & 20MW WTG (WNI & WNII)

Client: Tree Composites

Location: International Waters

Project overview

Enersea supported Tree Composites with the concept and basic design of WTG jacket foundations using conventional steel and wrapped composite technology. The aim of the projects was to assess the (large) potential cost savings by using jackets with composite nodes compared to steel jackets with conventional welded nodes. Jackets of these sizes are designed for next-generation offshore wind turbines — a 14MW Siemens Gamesa (SGRE) turbine for WrapNode I (WNI) and a 20MW turbine for WrapNode II (WNII).

Our engineering scope included:

- Concept and basic design of both conventional steel and WrapNode jacket foundations

- Iterative load assessments using time series data from Siemens Gamesa for both turbine types

- Close collaboration with Tree Composites, Siemens Gamesa and other project partners to ensure optimised foundation designs.

Project significance

Why WrapNode?

- Prefabricated composite joints for efficient fabrication

- Superior fatigue performance compared to traditional welded nodes

- Integrated joint and corrosion protection for extended design life

With this project, Enersea contributes to advancing innovative foundation solutions that support the growing scale of offshore wind turbines.

Client: Tree Composites

Location: International Waters

Project overview

Enersea supported Tree Composites with the concept and basic design of WTG jacket foundations using conventional steel and wrapped composite technology. The aim of the projects was to assess the (large) potential cost savings by using jackets with composite nodes compared to steel jackets with conventional welded nodes. Jackets of these sizes are designed for next-generation offshore wind turbines — a 14MW Siemens Gamesa (SGRE) turbine for WrapNode I (WNI) and a 20MW turbine for WrapNode II (WNII).

Our engineering scope included:

- Concept and basic design of both conventional steel and WrapNode jacket foundations

- Iterative load assessments using time series data from Siemens Gamesa for both turbine types

- Close collaboration with Tree Composites, Siemens Gamesa and other project partners to ensure optimised foundation designs.

Project significance

Why WrapNode?

- Prefabricated composite joints for efficient fabrication

- Superior fatigue performance compared to traditional welded nodes

- Integrated joint and corrosion protection for extended design life

With this project, Enersea contributes to advancing innovative foundation solutions that support the growing scale of offshore wind turbines.